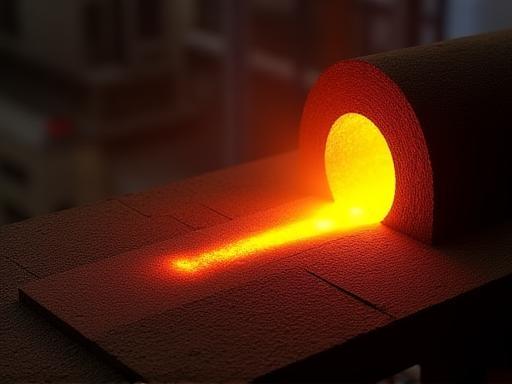

About Korea Forging Technologies

Korea Forging Technologies was established with a vision to redefine the forging industry through innovation, quality, and an unwavering dedication to customer satisfaction. Rooted in decades of accumulated forging expertise, our company has grown from a local enterprise to a globally recognized leader in providing advanced forging solutions. Our journey began with a small team of passionate engineers and metallurgists who shared a common goal: to deliver forging products that not only meet but exceed the highest industry standards. Over the years, we have consistently invested in state-of-the-art technology and fostered a culture of continuous improvement, enabling us to expand our capabilities and serve a diverse range of industries including automotive, aerospace, and construction.

At the heart of Korea Forging Technologies is a commitment to integrity, precision, and a relentless pursuit of excellence. We believe in forging strong, lasting relationships with our clients, understanding their unique needs, and providing tailored solutions that drive their success. Our mission is to be more than just a supplier; we aim to be a strategic partner, contributing to the progress and innovation of the industries we serve. We operate with a deep respect for our craft, ensuring every forging we produce is a testament to our expertise and dedication to quality. As we look to the future, Korea Forging Technologies remains committed to pushing the boundaries of forging technology, driving industry advancements, and upholding our promise of superior quality and customer satisfaction. We are not just forging metal; we are forging the future of industries, building a legacy of excellence and innovation that will endure for generations to come.

Our Mission Statement:

To be the leading global provider of forging solutions, driving industry progress through relentless innovation and an unwavering commitment to quality. We strive to empower our clients to excel in their respective industries by delivering superior forging products and services that consistently exceed expectations, fostering long-term partnerships built on trust, reliability, and mutual success. Our mission is to shape a stronger future, one forging at a time, contributing to the advancement of global industries and setting new benchmarks in forging technology and customer satisfaction.